Introduction: How to Broach a Keyway

Woodruff Keyseat cutters are designed for cutting keyways and keyseats as well as performing general purpose milling operations. Straight tooth cutters produce a better surface finish than staggered tooth. High Speed Steel is great for general purpose machining of all types of materials ranging from Aluminum alloys to alloy steels. A slot milled in a single step will not have a perfectly square form due to the direction of the cutting forces and the tendency of the tool to bend. The best accuracy and productivity will be achieved if the operation employs an undersized end mill, and is divided into two. Key slot milling – roughing of full slot Side milling – finishing all around the slot, using up-milling to create true square corners The radial depth of cut should be kept low in finishing operations to avoid deflection of the cutter, which is a major cause of bad surface finish and/or deviation from a. Keyseat End Mills Use these end mills for general purpose keyseat cutting in a wide range of material, including aluminum, iron, and steel. They mill precise notches in rotary shafts to fit machine keys and can also be used for slot milling.

Keys are an important part of mechanisms. They provide a solid and reliable interface between shafts and a wide variety of other objects including pulleys (as in my case), sprockets, levers and gears. There are a variety of different types of keys, but the simplest and most common is the straight key.

For this project, I'll be broaching keyways in some pulleys that I'm in the process of machining (still need to finish up the OD). The material is 6061 aluminum, it's 3/8' thick with a ø3/8' hole and I'll be broaching a 3/32' keyway.

Step 1: Tools and Materials

Tools:

Broach Kit, including a broach, shims (as needed) and the appropriate bushing.

Arbor or Hydraulic Pres

Materials:

Cutting Oil, my favorite is Tap Magic

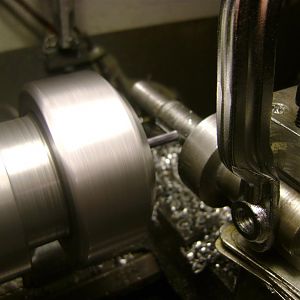

Step 2: Setting Up

This is a small broach in soft material, so I can easily use the 3 ton arbor press. If you're broaching a tougher material and/or a larger broach, you'll need a hydraulic press, as large broaches can require thousands of pound of pressure to cut. Also, larger broaches are much longer and often do not fit in an arbor press.

For this setup, I've selected the ø3/8' bushing, and the 3/32' broach. They should fit together well, sliding easily without any slop. Since the keyway is so small, I will not be needing any shims, which are used with larger broaches.

Insert the bushing into the hole you wish to broach. It should drop in easily. Next, rotate the slot to where you wish to cut the key. Liberally lube up the broach with your favorite cutting oil and and insert the broach into the slot in the bushing. The first quarter or so should slid in easily before the teeth engage with the part.

Step 3: Broaching

Align the part with the gap in the press and ensure the broach is straight up and down. Then apply even pressure, ensuring that the part is not tilting or rocking off the arbor press work surface. In aluminum it requires little effort. Be prepared to catch the broach as it reaches the end of its stroke- it may fall out. If the broach remains stuck in the part, use a small punch or piece of stock to press it all the way out. Do not strike the broach, as you can mushroom the end (sometimes imperceptibly) and cause yourself a big headache. Only press a broach.

Step 4: Resetting & Test Fitting

With the broach removed, use a chip brush to remove the swarf from the broach. It's important to clean these chips before broaching another keyway. Failure to do so can result in the broach jamming in the bore.

Now, we can take a key and test fit the freshly broached pulley with a shaft. It's a perfect fit. Often times I purchased shafts that already have the keyway machined in them. They are available from McMaster Carr.

Be the First to Share

Recommendations

Anything Goes Contest

Make it Real Student Design Challenge

Block Code Contest

Meet Our Product Brands

KEO Solid Round Tools

KEO was built on cutting edge manufacturing, on imagination and an unbeatable determination to make you more productive. Almost 80 years later we still hold true to that promise, providing all the legacy tools you know today and in addition, new high-performance carbide and material specific coated tooling for today’s most demanding applications. KEO will continue to be at the forefront of innovative solutions, in sophisticated applications, and in every manufacturing industry across America.

Ultra-Dex

Keyseat Cutter

Ultra-Dex prides itself on delivering the highest quality and best value products and services to our customers. Ultra-Dex manufactures a variety of indexable cutting tools, specializing in boring, milling, drilling, tool holding and inserts. Over the last several years we have dramatically increased the scope and breadth of our product offering and we will continue to so going forward, in response to the needs of our growing and successful customer base.